Design and simulate

Factory I/O includes more than 20 scenes inspired by common industrial applications. Use a library of industrial parts and extend Factory I/O by creating your own training scenarios.

30-day free trial • Ultimate Edition included • Full-featured

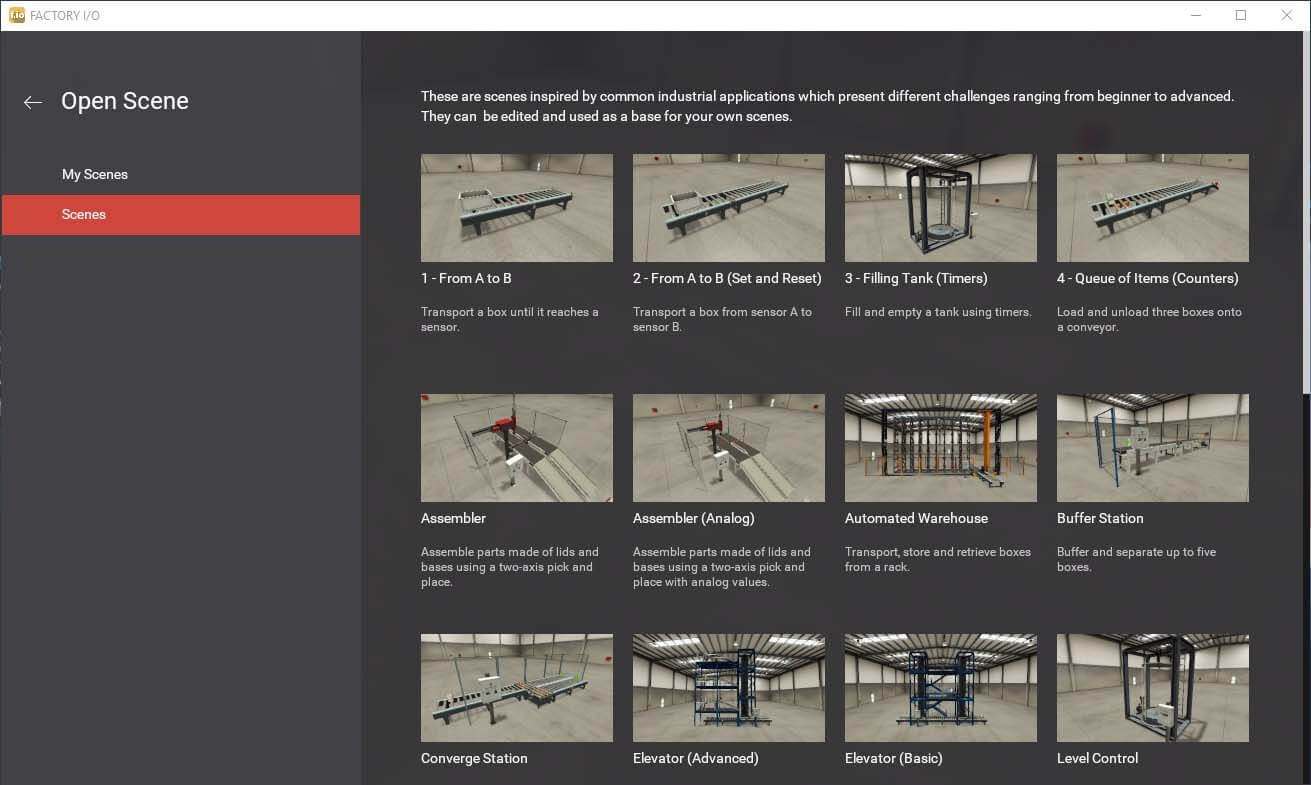

20+ ready-to-use scenes

Factory I/O offers more than 20 scenes inspired by typical industrial applications to practice real world control tasks. Use a scene as it is or as a starting point for a new project.

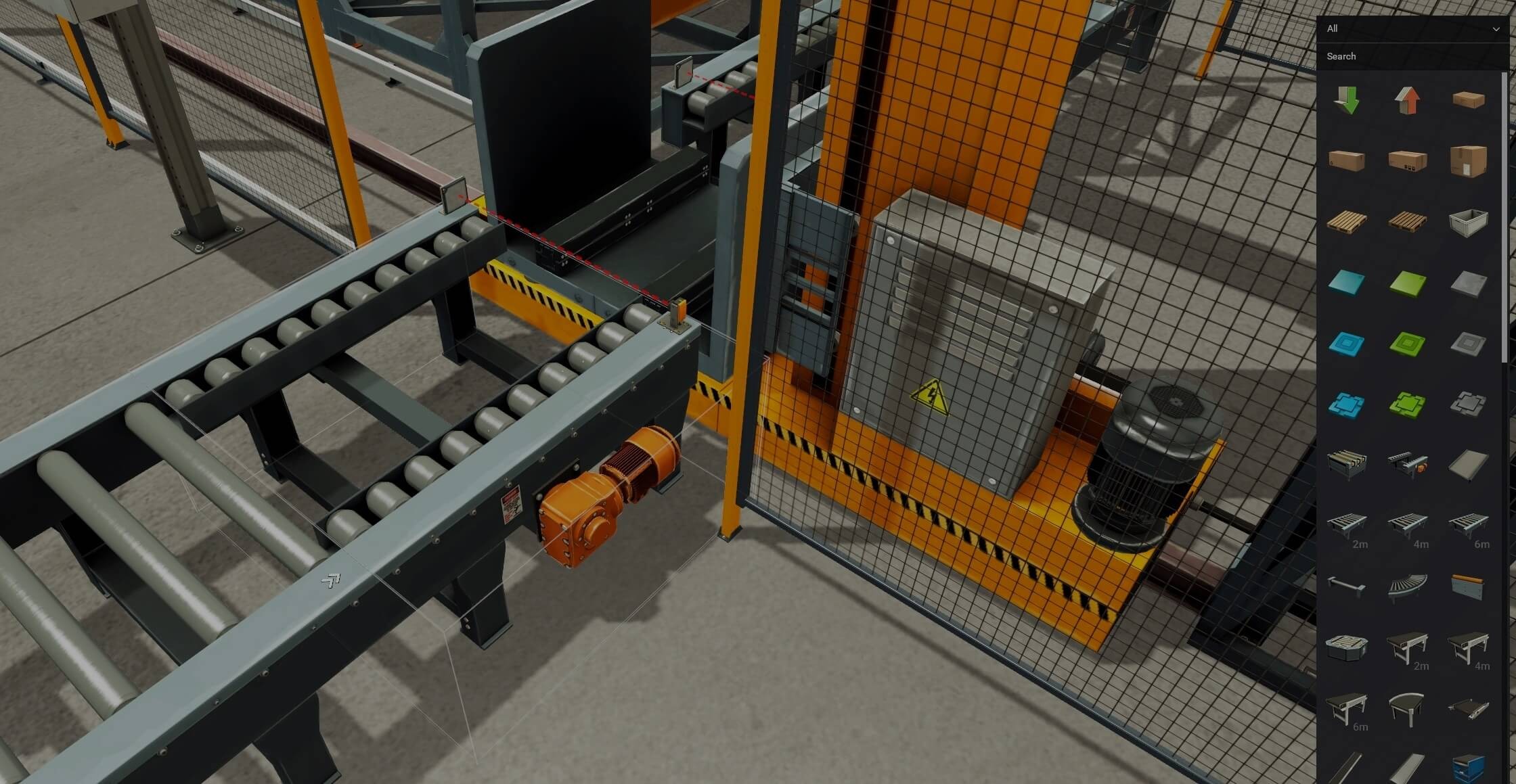

Library of industrial parts

Create a virtual factory using a library of industrial parts, including sensors, conveyors, elevators, stations, and many others.

Build your own scenarios

Factory I/O smart editing tools make building a 3D scene a comfortable and natural experience. Use a library of industrial parts and customize Factory I/O by creating your own training scenarios.

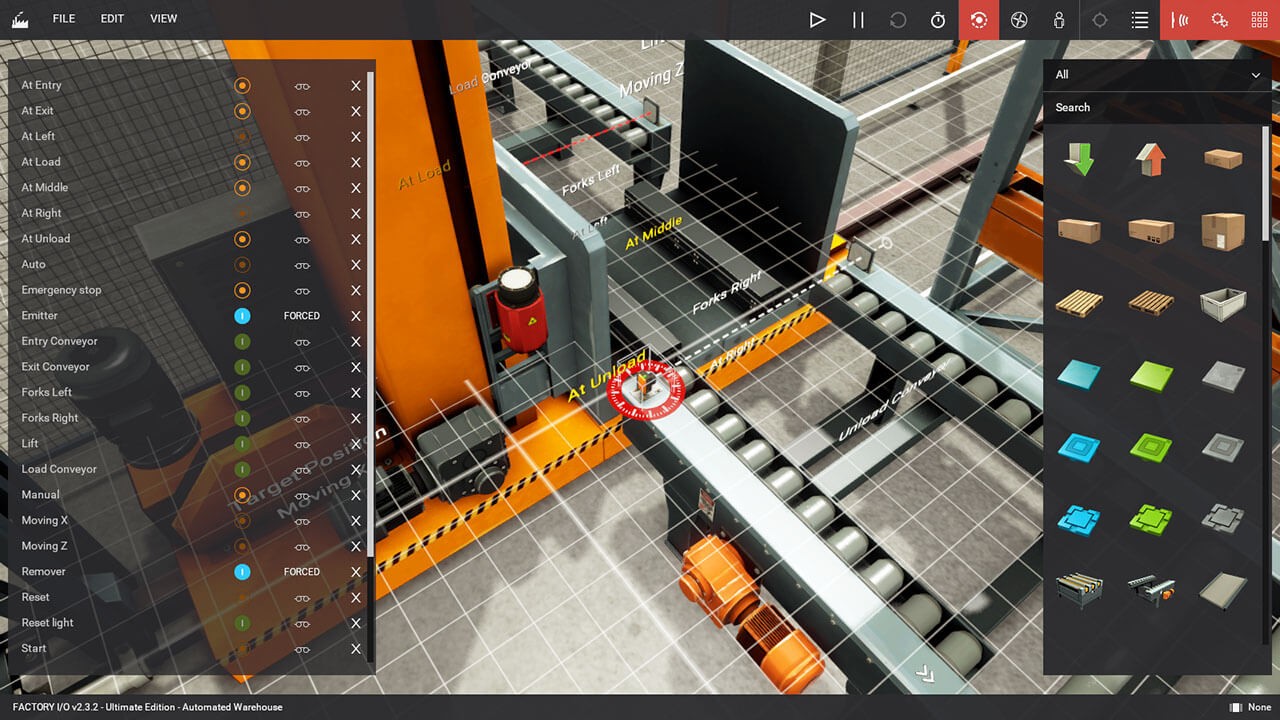

Digital & analog I/O

Most parts include digital and analog I/O. For example, use a digital value to start or stop a conveyor or an analog value to weigh items or control liquid levels.

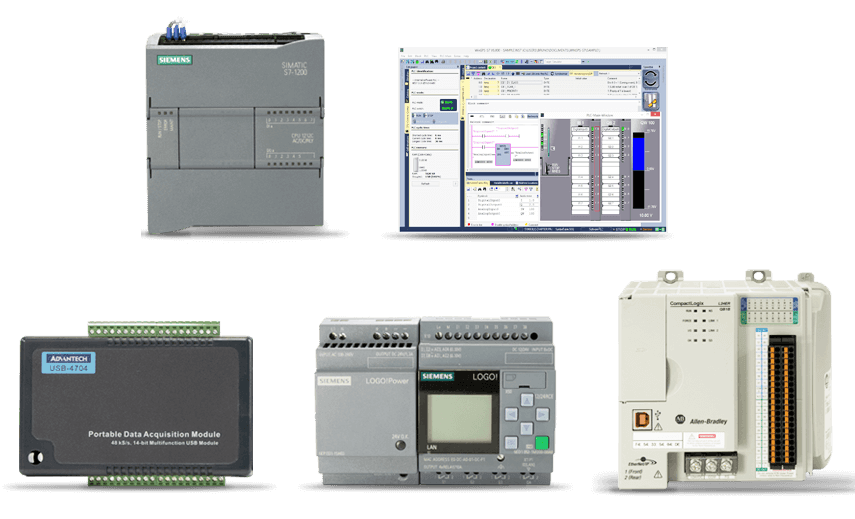

I/O drivers

Factory I/O uses drivers to interface with PLC, SoftPLC, PLC simulators, Modbus and many other technologies. Each edition includes a bundle of drivers for a specific technology (i.e. Allen-Bradley Edition, Siemens Edition, …).

Troubleshooting

Practice troubleshooting routines by easily injecting Always On and Always Off failures in sensors and actuators.

Instructor mode

Lock several options with an instructor password. Challenge trainees to complete partially built systems, find malfunctions and failures.

Easy integration

Easily integrate Factory I/O with existent training equipment. Plug and Play with Siemens and Allen-Bradley PLC (Ethernet). May require wiring for other brands through interface boards.

Advantages

One license includes 20+ ready-to-use industrial applications

Can teach a whole classroom simultaneously

Works with all PLC brands and the most common automation technologies

Takes only 600Mb of disk space

Move it anywhere

Students can experiment, edit and modify their virtual factory without risks

An inherent feature of simulations: no wear

Ready to start?

Download Factory I/O 30-day free trial. Includes full-featured Ultimate Edition.

Available editions

Factory I/O is available in 7 different editions. Each edition includes I/O drivers targeting specific technologies.

Compare all editions